KERAVETTE

UNCOMPLICATED. GLAZED. OR UNGLAZED.

ALSO REGARDING COST-EFFECTIVENESS. UNOBTRUSIVE AND YET STILL IMPRESSIVE.

Keravette gives a facade a new unmistakeable and individual look. No wonder the word “facade“ has been adopted from the Italian word “faccia“ meaning “face”.

24 beautiful colour tones, numerous formats and glazed or unglazed surfaces give you a nearly unlimited choice of options. So each facade quite easily becomes unmistakeable.

The material thickness of 8 and 11 mm means this classic among clinker brick slips is not only light but, thanks to the especially high firing temperature, it is also extremely robust. Together with modern thermal insulation, they are also hard to resist when it comes to price.

KERAVETTE

PROJECTS AND REFERENCES

Mompiano Swimming Centre

Brescia, Italy

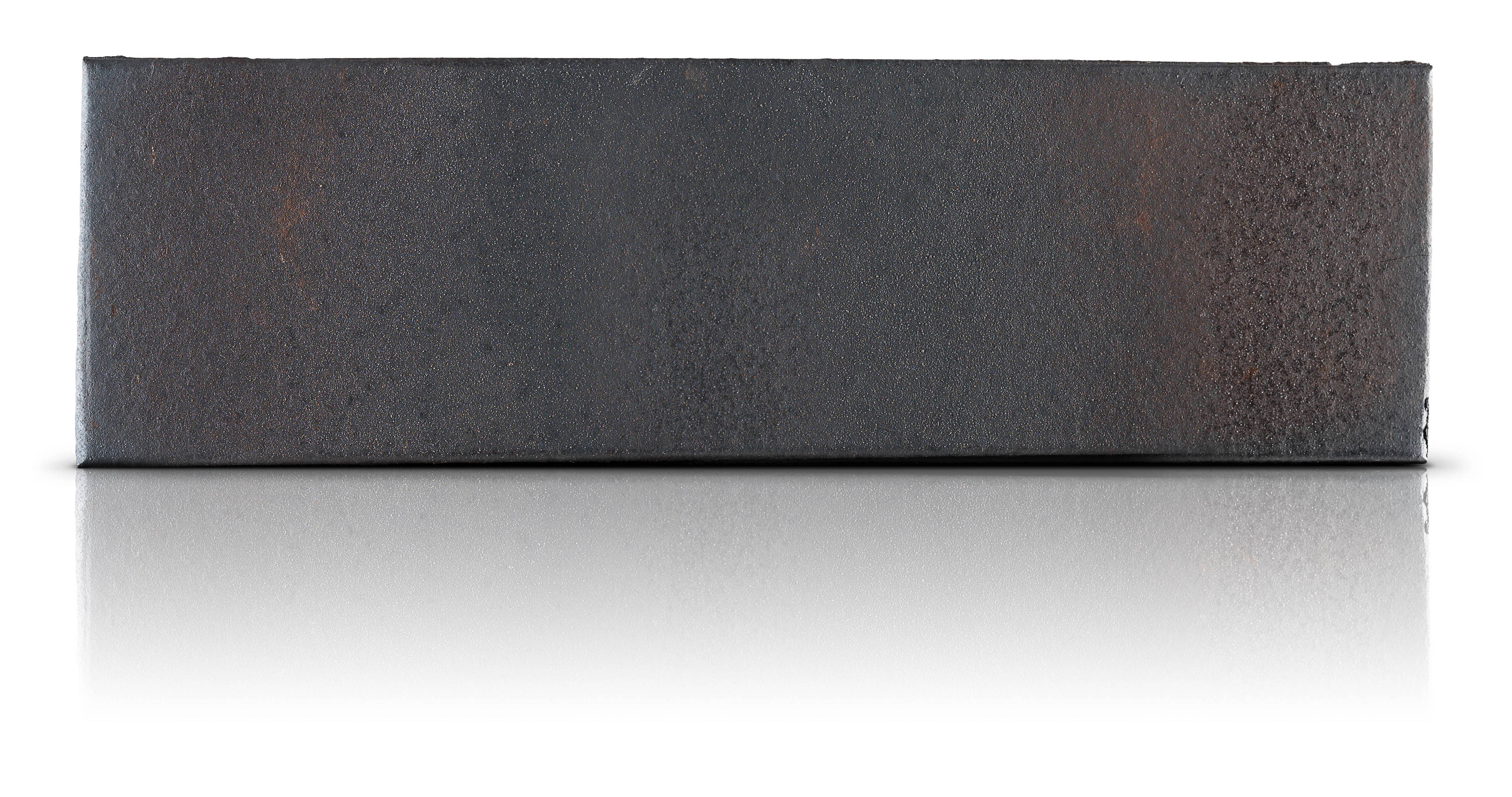

Keravette® 336 metallic black

Garnmarkt

Götzis, Austria

Keravette® 200 saumon

Kenyon Street

Birmingham, England

Keravette® 320 sand yellow

Campus II

Dornbirn, Austria

Keravette® 336 metallic black

Small Residential Complex

Innsbruck, AustriaKeravette® 336 metallic black

KERAVETTE®

LAYING HINTS

Window lintel perfectly replicated with angles.

The corner angles are worked using the floating-buttering method.

Use a string to plumb the clinker area. The clinker slips are pressed into the adhesive bed.

The finished surface. Grouting can be done after the appropriate drying time.

With the slurry method, the joints are filled diagonally with the grouting or plaster float. Walls should be worked from top to bottom.

The excess grout is washed off diagonally using a plaster float with a sponge or foam pad.

The finished joint pattern after slurry treatment.

product details

technical specifications, downloads

| Description | Clinker brick slips | corner | corner | |

| Nominal size | NF | NF | NF | |

| Production size (mm) | 240 x 71 x 11 | 240 x 115 x 71 x 11 | 175 x 71 x 52 x 11 | |

| pieces per bundle | 26 | 16 | 28 | |

| pieces per m2/rm incl. joint | 50,00 | 12,50 | 12,50 | |

| pieces per pallet | 2496 | 1040 | 1680 | |

| m2/rm per bundle | 0,52 | 1,28 | 2,24 | |

| m2/rm per pallet | 49,92 | 83,20 | 134,40 | |

| bundles per pallet | 96 | 65 | 60 | |

| kg per pallet | 996,00 | 664,00 | 603,00 | |

| kg per piece | 0,40 | 0,64 | 0,36 | |

| kg per m2/rm | 19,95 | 7,98 | 4,49 | |

| kg per bundle | 10,37 | 10,21 | 10,05 |

| DIN EN 14411 | |

| COLOURS: | 0788 royal, 0747 sherry, 0707 white, 0785 graphite, 0741 brown, 0728 palace, 0729 achatblue-flashed, 0725 patrician red, 0783 metallic black, 0727 patrician red flashed |

| FORMATS: | NF |

| Water absorption (Average value) (EN ISO 10545-3) | ≤ 3 % |

| Scratch hardness of surface (Mohs scale) (minimum individual value) (EN 101) | 6–7 |

| Frost resistance (EN ISO 10545-12) | is fulfilled |

| Chemical resistance – except to hydrofluoric acid and its compounds – of tiles (EN ISO 10545-13) | is fulfilled |

| Thermal shock resistance (EN ISO 10545-9) | is fulfilled |

| Coefficient of thermal expansion from room temperatur (20° C) to 100° C/CE (EN ISO 10545-8) | < 80x10-7K-1 |

| Maximum pore radius (required: rp > 0,2 μm) (DIN 66 133) | 0,50 μm–1,67 μm |

| Pore volume (required: Vq > 20 mm3/g) (DIN 66 133) | 31,1 mm3/g–63,2 mm3/g |

| Water absorption (Average value) (EN ISO 10545-3) | ≤ 3 %, 0707 white, 0785 graphite: ≤ 6% |

| Scratch hardness of surface (Mohs scale) (minimum individual value) (EN 101) | 6–7 |

| Frost resistance (EN ISO 10545-12) | is fulfilled |

| Chemical resistance – except to hydrofluoric acid and its compounds – of tiles (EN ISO 10545-13) | is fulfilled |

| Thermal shock resistance (EN ISO 10545-9) | is fulfilled |

| Coefficient of thermal expansion from room temperatur (20° C) to 100° C/CE (EN ISO 10545-8) | < 80x10-7K-1 |

| Maximum pore radius (required: rp > 0,2 μm) (DIN 66 133) | 0,27 μm–6,80 μm |

| Pore volume (required: Vq > 20 mm3/g) (DIN 66 133) | 22,8 mm3/g–59,8 mm3/g |